| |

|

Projects / Toilet Soap Finish Line

Applications of Soap Making Machine

We manufacture machines for specific applications which have superior performance along with lasting power. We manufacture machines for toilet soap, detergent bar soap, laundry soap, detergent powder, hotel soaps etc. We offer the complete Plant on turn key basis along with the Know- How to make the soap either from Soap Noodles, Palm Oils, Fatty Acid etc, Plants and machines manufactured by us are based on proven technologies presently operating successfully, in India and Overseas.

Hence, there is no delay in commissioning of plants & machinery manufactured by us. We guarantee 100% hassle free production, from day one of commissioning.

|

| |

PRODUCTS:

Toilet Soap Finish Line

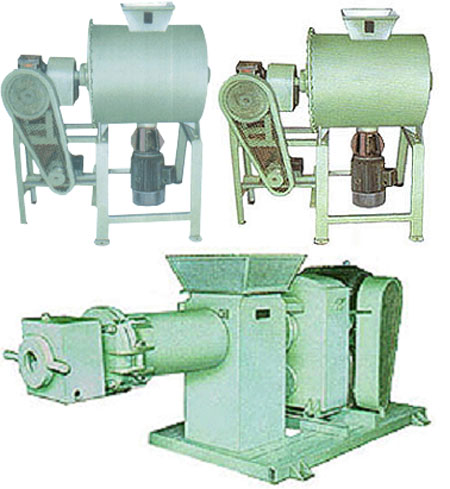

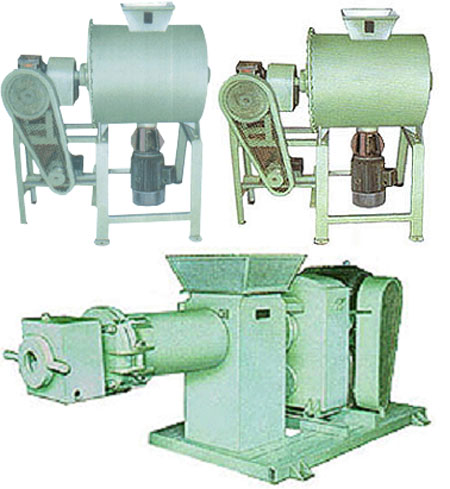

1. Sigma Mixer

2. Pelletizer

3. 3 Roll Mill

4. 3 Roll Mill Straight

5. Conveyor

6. Duplex Plodder

7. Disc Cutter

8. Reciprocating Cutting Machine

Quality Assurace

Plants and machines manufactured by us are based on proven technologies presently operating successfully, in India and Overseas.

Hence, there is no delay in commissioning of plants & machinery manufactured by us. We guarantee 100% hassle free production, from day one of commissioning.

Capacity offered by us range from 50 Kgs to 2000 Kgs Per hour.

We also offer Table Top Pilot Plant 10/25 kgs per hour.

|

|

| |

|

Saponification & Drying Section

Process of noodles making involves saponification, vacuum spraying and drying operations. Noodles are either made from OILS/ fatty acids or animal tallow. Fatty acids like palm fatty/palm kernel/palm stearine can be imported from Malaysia which is the cheapest source in the world. Animal tallow can be imported from Germany or European countries. The process which we have offered needs refined animal tallow or 80/20 proportion of palm and coconut fats or refining and blending of locally availableoils. If the soap base is not refined, white colored soap noodles cannot be manufactured. These will be little off white in color. White soap noodles are preferred because any light colored soap can be made. For toilet soap, generally 78% TFM( total fatty matter) noodles are used. As TFM value decreases, soap quality decreases. Storage tanks can be designed as per the requirement of inventory depending upon import schedules and other commercial factors. Boiler fuel can also be selected as per local availability. You can also make your own Raw material using the Saponification Process

|