|

|

|

|

|

|

| |

:: OUR PRODUCTS :: |

Crushing and Pulverising / Ball Mills |

|

|

| |

|

|

| |

|

| |

|

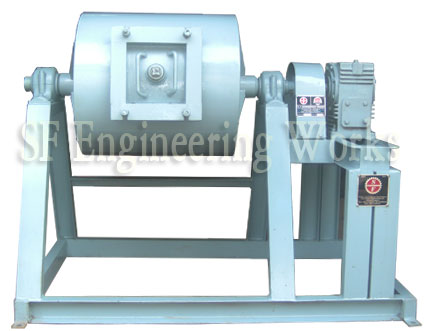

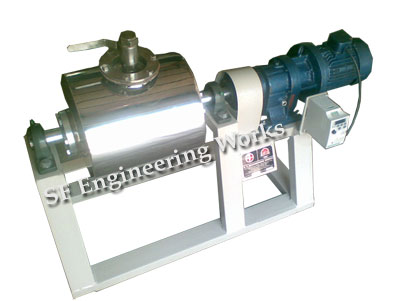

Ball Mills

One of the oldest and safest methods for grinding of a wide range of materials of hardness upto 8 on mohs scale. Can be used for grinding of Practically any material wet,dry or sticky.

SIZE

|

HP

|

TOTAL

VOL CAP IN LTRS |

12x18

|

1 |

50 |

20x20

|

2 |

100 |

2’x2’

|

3 |

175 |

3’x3’

|

5 |

500 |

4’x4’

|

10 |

1500 |

5’x5’

|

15 |

2200 |

6’x6’

|

25 |

4750 |

|

|

| |

BALL MILL:

Size --- Material Of Construction Mild Steel. Having Total Volume Capacity In Liters ---. Main Shell Will Be Fabricated In ---Mm Thick Plate And Side Plate Will Be --Mm Thick And Further Supported And Stiffened With Mild Steel Heavy Duty Ribs And Backing Plates To Withstand Heavy Loads From Outside. Main Shaft Will Be ---Mm Dia Located On Heavy-Duty Bosses And Rotate On Roller Bearings Complete With Plumber Blocks And Sleeve Nuts. A Discharge Door Main Hole Of The Cylinder Will Be ---------- For Liquid Or Solid Discharge Is Provided With The Mill Along With Manhole Cover If Required. Main Shaft Will Be Turned Through From One End To Another End. The Entire Mill Is Mounted On A Sturdy Frame Structure Made From ISMC Sections.

Hence Complete With Material As Per Our Standard Design.

Drive:

A -- Hp 3 Phase 50 Cycle 440=/-V Motor Coupled To A Worm Reduction Gear Box Of -- Center, Is Mounted On A Separate Base Frame And Drives The Mill At -- Rpm.

A Girth Gear With Matching Pinion Is Fitted On Mill Of Size 4' Dia. And Above.

Note:

Working Capacity Will Be 25 To 35% Of Total Capacity After Loading Grinding Media. Grinding Media To Be Loaded 40 To 60% Of Volume Depending On Material To Be Ground.

|

|

SIZE |

CONTAINER CAPACITY |

SHELL THICKNESS |

GEAR BOX |

LID SIZE OPENING |

SHAFT SIZE |

MOTOR HP |

2' X 2' |

175 |

10 |

3” |

10” X 10” |

60 MM |

2 |

2'6" X 2'6" |

325 |

10 |

3” |

10” X 10” |

60 MM |

3 |

2'6" X 3'6" |

440 |

10 |

3” |

10” X 10” |

60 MM |

5 |

3' X 3' |

590 |

10 |

4” |

12” X 12” |

75 MM |

5 |

3'6" X 3'6" |

900 |

10 |

4” |

12” X 12” |

75 MM |

7.5 |

4' X 4' |

1400 |

14 |

5” |

14” X 14” |

100 MM |

10 |

4'6" X 4'6" |

1600 |

14 |

5” |

14” X 14” |

100 MM |

15 |

5' X 5' |

2200 |

16 |

6” |

15” X 15” |

125 MM |

20 |

6' X 6' |

4750 |

19 |

9” |

16” X 16” |

150 MM |

25 |

7’ X 7’ |

7600 |

20 |

10” |

16” X 16” |

175 MM |

75 |

8’ X 8’ |

11000 |

22 |

12” |

20” X 20” |

200 MM |

100 |

Note: Working capacity to be calculated at 50% of container capacity.

BALL MILL WITH HOPPER M.O.C. (MILD STEEL) |

SIZE |

4' X 4' |

5' X 5' |

6' X 6' |

8’ X 8’ |

CONTAINER CAP LTRS |

1400 |

2750 |

4800 |

11,000 |

BATCH SIZE LTRS |

600 |

1100 |

1920 |

10,000 |

SHELL THICKNESS |

14 |

16 |

19 |

19 |

SIDE PLATE |

16 |

20 |

25 |

25 |

HOPPER THICKNESS |

3MM |

3MM |

3MM |

3MM |

HOPPER SIZE |

5’ X 5’ |

6’ X 6’ |

7’ X 7’ |

10’ X 10’ |

HOPPER TYPE |

2 HALF FOLDING |

2 HALF FOLDING |

2 HALF FOLDING |

2 HALF FOLDING |

REDUCTION GEAR BOX |

5” |

6” |

9” |

12” |

LED SIZE OPENING |

14” X 14” |

15” X 15” |

16” X 16” |

24” X 24” |

SHAFT SIZE |

100 MM |

125 MM |

150 MM |

150MM |

MOTOR HP |

15 |

30 |

50 |

100 |

FINAL SPEED |

23 |

21 |

19 |

20 – 22 |

Note:

Working Capacity Will Be 25 To 35% Of Total Capacity After Loading Grinding Media. Grinding Media To Be Loaded 40 To 60% Of Volume Depending On Material To Be Ground.

TABLE INDICATING THE OPTIMUM MILL SPEED AND MOTOR OF BALL MILLS

Inside Dia

mm |

Inside Length mm |

DRY GRINDING |

WET GRINDING |

Speed (RPM) |

Motor Power (HP) |

Speed (RPM) |

Motor Power (HP) |

Steatite

media |

Alumina

media |

Steatite

media |

Alumina

media |

Steatite

media |

Alumina

media |

Steatite

media |

Alumina

media |

300 |

300 |

60 |

54 |

½ |

½ |

46 |

38 |

½ |

½ |

450 |

450 |

50 |

44 |

½ |

½ |

37 |

31 |

½ |

½ |

600 |

600 |

43 |

38 |

1 |

1 |

33 |

27 |

1 |

1 |

750 |

750 |

39 |

34 |

1½ |

1½ |

29 |

24 |

1½ |

1½ |

900 |

900 |

35 |

31 |

2½ |

3 |

27 |

22 |

2½ |

3 |

1050 |

1050 |

33 |

29 |

5 |

5 |

25 |

20 |

4½ |

4½ |

1200 |

1200 |

31 |

27 |

7½ |

7½ |

23 |

19 |

6½ |

6½ |

1350 |

1350 |

29 |

25 |

12 |

15 |

22 |

18 |

8 |

12 |

1500 |

1500 |

27 |

24 |

15 |

15 |

21 |

17 |

12 |

15 |

1800 |

1800 |

25 |

22 |

25 |

30 |

19 |

16 |

20 |

25 |

2100 |

2100 |

23 |

20 |

37 |

40 |

17 |

15 |

30 |

37 |

2400 |

2400 |

22 |

19 |

55 |

75 |

16 |

14 |

45 |

55 |

2700 |

2700 |

20 |

18 |

90 |

100 |

15 |

13 |

75 |

100 |

3000 |

3000 |

19 |

17 |

125 |

150 |

15 |

12 |

100 |

125 |

|

|

|

|

|

|

| |

|

Copyright © 2008 sf engineering works.. All Right Reserved. |

|

|

Designed by JB Software Solutions |