|

|

|

|

|

|

Home |

Client List |

Careers |

Contact Us |

Site Map |

| About Us | Machines | Plants & Projects | Services | Why Us? | News | More Links |

:: OUR PRODUCTS ::

Crushing and Pulverising / Jar Mills

|

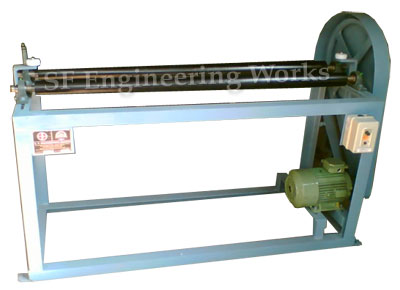

Jar Mills For lab grinding of wet or dry material. Is a machine where jars and media of different materials of construction can be used to determine grinding results. Is used by the paint, ink, dyestuff, chemical, electronic and pharmaceutical industries prior to scale up application in ball mills.

APPLICATION: |

||||||||||||||||

|

|||||||||||||||||

EXTRA ACCESSORIES AVAILABLE:

GRINDING MEDIA: (Minimum Quantity 50 Kgs.) Porcelain Balls.

Click Here for Download Brounchers |

|||||||||||||||||