| |

|

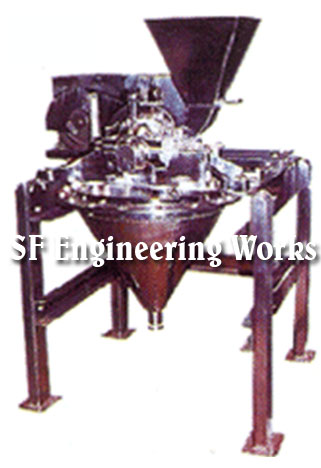

Suitable for grinding of wet or dry material of medium hardness upto 4 on mohs scale such as food products, dyestuff, pharmaceutical products, cattle feed dry fish, fibrous products etc.

SIZE

|

HP |

APPROX

CAP IN KGS/HR. |

| SFMP 1 |

2 |

10 |

| SFMP 2 |

5

|

20-25 |

| SFMP 3 |

10 |

50-70 |

|

|

| |

PRINCIPLE:

SF Micro Pulveriser is a rugged, high capacity, low maintenance, economical unit designed to produce specified grinding and smooth blending results. Grinding is done under cool atmospheric air, thus retaining the original colour, taste and fragrance of the ground material. The powder obtained is as good as hand ground powder. Frigmaires Micro Pulveriser not only grinds the feed material but also blends and disperses the same in a single dustless operation. The maximum mesh obtainable will be approx.250 Mesh.

Principle of pulverizing :

MICRO PULVERIZER consists of a rotor assembly fitted with hammers (beaters) & is generally operated at high speeds.

The grinding action in all the pulverizers is due to the impact between rapidly moving hammers (beaters) & the particle itself. The energy of the moving hammers is dissipated into the particles being ground by virtue of their inertia, thus causing the particle size reduction.

Rotor shaft assembly :

The rotor shaft is made of suitable quality steel & is assembled with beater assembly & sufficient number of bearings to withstand the loads caused by high - speed revolutions & the impact of beaters & the particles.

Beaters :

These are a set of hammers revolving at high velocity inside the grinding chamber. The beaters are surface hardened . Special types of beaters are provided for heat sensitive materials.

Liner:

The multiple deflectors or the serrations provide multiple breakers for still further reduction of the particle size by virtue of impact between the rapidly moving particles & the multiple deflectors. The liner enhances the ultra - fine pulverizing because the particles break down by the force of impact against the breakers. These are specially designed to minimize heat due to the impact of beaters on the particles being pulverized.

Retaining Screen :

The screens are replaceable & are available in various mesh sizes. Their function is to hold the material in the grinding chamber until the particles are ground to the required degree of fineness. The particle size is not accomplished by the screens.

Feeding Arrangement :

The material to be pulverized is fed to the grinding chamber in two different ways:

Screw feeding :

The material to be ground is fed to the grinding chambers in a uniform way by screw feeders, which are driven by an electric motor. It consists of a complete feeding assembly containing one or three feed screws coupled with suitable reduction gears designed for regulated feeding into the grinding chamber.

|

Direct feeding

The material to be ground is uniformly fed to the grinding chamber by gravity with the help of feed valve. This type of arrangement is extremely successful for materials, which cannot be conveyed into the grinding chamber due to their light - weight or due to their size. Gravity feeding can be used to pulverize materials like sugar, salt or carbon, as these types of material are extremely easy to grind. It gives the same order of fineness as the screw-feeding unit does & completely eliminates the screw feeding assembly.

SALIENT FEATURES:

Compact, Rugged Design :

Each part is precisely engineered from quality materials. The micro pulveriser grinds, blends & disperses in a single dustless operation. Rugged, accurate & carefully designed, it assures increased capacity & longer machine life.

No auxiliaries :

The finished product in a pulverizer is a result accomplished without the aid of cost consuming auxiliaries such as fans, air separators, classifiers, cyclones etc.

Dust free operation :

The accurately machined surfaces ensures effective sealing against dust, leakage while the machine is still in operation.

Quick & Easy cleaning :

Cleaning is greatly simplified due to the absence of auxiliaries. The simplicity of design also makes all parts easily accessible for fast cleaning & inspection. Easily cleaned & inspected, it saves labour & reduces the maintenance costs.

Water Cooling System :

A water-cooling system is provided for cool grinding.

Air Balloon :

Air balloon is provided which eliminates the back pressure and cools warm air circulating in the grinding chamber.

Note : All Details , description, specification, size, capacity, mesh, etc. are approximate & For General Reference & will depend upon the nature of your material only.

MODEL |

MP6 |

MP6 |

MP7 |

MP8 |

MP12 |

MP18 |

CHAMBER SIZE |

6" |

6" |

7" |

8" |

12" |

16" |

HORSE POWER |

1.5 |

2 |

3 |

5 |

10 |

20 |

CAP. PER/HR. |

5/10 |

10/25 |

25/50 |

50/75 |

75/150 |

150/200 |

RPM |

3000 |

3000 |

3000 |

3000 |

1500 |

1500 |

Please Click Here Download Brouchers

|

|